What Healthcare Professionals Want in a Modular OR?

introduction

The evolution of modular operating rooms (modular OR) is redefining the landscape of surgical care. As healthcare demands intensify and technology advances, clinicians, surgeons, and hospital administrators are seeking modular OR solutions that deliver not only flexibility and efficiency but also uncompromising safety and future-readiness. This article explores what healthcare professionals are looking for in a modular operating room, drawing on the latest trends, standards, and innovations up to 2025.

The Core of Modern Surgical Rooms: Why Modular ORs Are in Demand

What is a Modular Operating Room?

A modular operating room is a surgical environment constructed using prefabricated, standardized components that can be rapidly assembled, configured, and upgraded. Unlike traditional brick-and-mortar surgical rooms, modular ORs are designed for speed, flexibility, and technological integration-making them ideal for today’s dynamic healthcare environments.

Key Features Healthcare Professionals Expect in Modular Operating Rooms

Infection Control and Hygiene

One of the foremost priorities for any surgical room is infection prevention. Modular ORs are engineered with:

- Seamless, Non-Porous Surfaces: Antimicrobial wall panels and seamless construction reduce microbial colonization and make cleaning more effective.

- Advanced Air Handling: HEPA-filtered, laminar-flow ceiling systems maintain ISO-class cleanroom standards, controlling airborne contaminants and reducing surgical site infections.

- Automated Disinfection: Integration of UV-C or aerosolized disinfection systems into walls and ceilings for routine, hands-free sterilization between cases.

These features are essential for meeting stringent infection control protocols and ensuring patient safety.

Rapid Deployment and Scalability

Healthcare professionals value modular ORs for their:

- Speed of Installation: Prefabrication allows for deployment in weeks rather than months, minimizing hospital downtime and enabling rapid response to surges in demand.

- Scalability: Modular “kit-of-parts” designs allow hospitals to expand or reconfigure surgical capacity as needed, supporting both permanent and temporary installations.

- Relocatability: Modules can be moved or repurposed for disaster response, field hospitals, or temporary expansions.

Standardization and Quality Assurance

Consistency and quality are critical for multi-site healthcare providers:

- Factory-Certified Components: Modular ORs are manufactured in controlled environments, ensuring compliance with global cleanroom and medical device standards.

- Prototypic Models and Templated Rollouts: Standardized designs allow for rapid replication across hospital networks, streamlining training and maintenance.

Hybrid and Integrated Technology

The modern operating theatre is a hub of digital and diagnostic technology:

- Hybrid OR Setups: Integration with C-arms, CT/MRI scanners, and robotic systems enables advanced procedures and intraoperative imaging.

- Edge-Device Networks: Real-time data capture and AI-driven decision support enhance surgical precision and workflow.

- Touch-Panel Controls and HIS Interoperability: Seamless integration with hospital information systems (HIS) for efficient scheduling, documentation, and device management.

Ergonomics and Workflow Efficiency

Optimizing the working environment is crucial for surgical teams:

- Ergonomic Furniture and Instrument Placement: Customizable layouts reduce fatigue and streamline surgical tasks.

- Clutter-Free Design: Ceiling-mounted pendants, lighting, and equipment reduce trip hazards and maximize usable space.

- Evidence-Based Layouts: Designs informed by multi-year studies of best-practice ORs to maximize efficiency.

Sustainability and Environmental Impact

Green surgery and sustainability are rising priorities:

- Energy-Efficient Systems: Advanced HVAC and LED lighting reduce energy consumption and operational costs.

- Life-Cycle Analysis: Modular components are designed for durability, reuse, and minimal waste, supporting net-zero or carbon-balanced facilities.

- Relocation and Reusability: Modular construction minimizes waste by allowing components to be reused or relocated as needs change.

Acoustic Environment and Staff Communication

Noise control is vital for safety and team performance:

- Acoustic Ceilings: Modular acoustic tiles reduce reverberation and facilitate quick maintenance.

- Noise Barrier Solutions: Designs address staff-reported noise challenges, improving communication and reducing errors.

Waste Reduction and Cost-Effectiveness

Fiscal responsibility and environmental stewardship go hand in hand:

- Efficient Supply Management: Workflow designs that reduce unused sterile supplies and minimize waste.

- Long-Term Savings: While upfront costs may be higher, modular ORs offer significant savings over time through reduced downtime, maintenance, and adaptability.

Operating Rooms Digitalization, Analytics, and AI

Data-driven operating theatres are transforming care delivery:

- Predictive Maintenance: Machine-learning models forecast equipment needs and optimize scheduling.

- Integrated Dashboards: Real-time links between vital signs, imaging, and device telemetry streamline decision-making and documentation1.

Regulatory Compliance and Standards

Navigating complex regulations is non-negotiable:

- Global Standards: Modular ORs are designed to meet ISO 14644, HTM 03-01, NFPA 99, ASHRAE 170, and other international cleanroom and medical safety standards.

- Certified Construction: Emphasis on CHC-certified practices ensures both safety and financial stewardship.

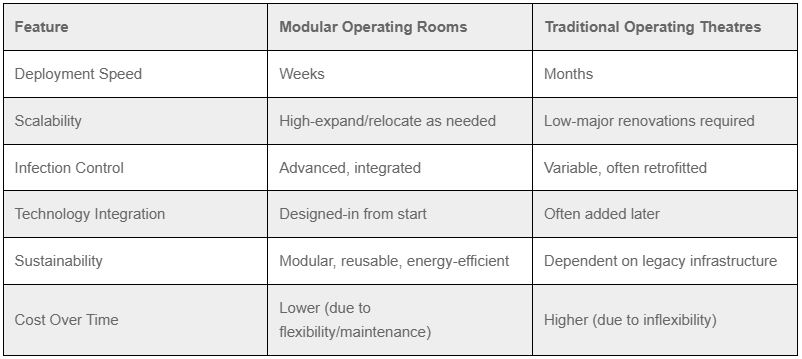

Modular ORs vs. Traditional Operating Theatres: A Comparison

What Sets Leading Modular Operating Rooms Apart?

Customization and Flexibility

- Modular ORs can be tailored to specific surgical specialties, from orthopedics to cardiology, with customizable wall panels, integrated displays, and specialty gas outlets.

Future-Proofing

- Designs anticipate future technology upgrades, ensuring that new imaging, robotics, or data systems can be integrated with minimal disruption.

Staff-Centric Design

- Input from surgeons, nurses, and infection control specialists is incorporated from the earliest design stages, ensuring the space works for everyone involved.

Modular ORs in Action: Real-World Applications

- Emergency Response: Rapid deployment of modular ORs has proven invaluable during pandemics and natural disasters, enabling hospitals to expand capacity almost overnight.

- Multi-Site Networks: Standardized modular ORs allow large health systems to maintain consistent quality and protocols across multiple locations.

- Specialty Centers: Modular design supports the creation of dedicated surgical suites for advanced procedures, such as minimally invasive or robotic surgery.

Frequently Asked Questions

What are the main benefits of modular operating rooms over traditional ones?

Modular ORs offer rapid deployment, superior infection control, easy scalability, and seamless integration of advanced technologies.

How do modular ORs help with infection control?

They feature seamless, non-porous surfaces, advanced air filtration, and automated disinfection systems to minimize infection risks.

Can modular ORs be customized for different surgical specialties?

Yes, modular ORs can be tailored with specialty equipment, layouts, and integrated technologies for various surgical disciplines.

Are modular operating rooms more expensive?

While initial investment may be higher, modular ORs provide long-term savings through reduced downtime, maintenance, and adaptability.

How quickly can a modular OR be installed?

Modular ORs can typically be deployed in weeks, significantly faster than traditional construction.

What standards must modular ORs meet?

They are designed to comply with ISO 14644, HTM 03-01, NFPA 99, ASHRAE 170, and other international cleanroom and safety standards.

How do modular ORs support sustainability?

They use energy-efficient systems, reusable components, and minimize construction waste, supporting green healthcare initiatives.

Can modular ORs be relocated?

Yes, modules can be moved or repurposed for temporary or emergency use, offering unmatched flexibility.

How do modular ORs enhance staff workflow?

Ergonomic design, clutter-free layouts, and integrated controls reduce fatigue and improve efficiency for surgical teams.

What digital features are available in modular ORs?

Integrated dashboards, real-time data capture, AI-driven analytics, and HIS interoperability are common in advanced modular ORs.

Ultravision: Your Partner for Advanced Medical Projects and Modular OR Solutions in the UAE

Comprehensive Medical Projects and Healthcare Solutions

When it comes to delivering world-class medical projects-from design to execution-Ultravision stands at the forefront. We specialize in advanced healthcare solutions for hospitals and clinics across the UAE, leveraging global expertise and local insight.

ALVO Modular OR: Flexible, Future-Ready Operating Rooms

As a trusted partner for ALVO modular OR solutions, Ultravision delivers:

- Rapid Assembly: Prefabricated panels and integrated systems enable installation in weeks, minimizing disruption to ongoing hospital operations.

- Scalable Design: Easily expand or reconfigure your ALVO operating rooms as your facility grows or surgical needs change.

- Advanced Automation: ALVO modular ORs support integrated displays, telemedicine, and surgical robotics for next-generation care.

- Compliance and Quality: All ALVO modular OR components meet the highest international standards for cleanroom and medical safety.

Why Choose Ultravision for Your Modular OR Medical Projects?

- Expertise in Medical Projects: From planning to aftercare, Ultravision manages every aspect of your hospital or clinic upgrade.

- Authorized medical Suppliers in UAE: We are recognized among the most reliable modular OR suppliers in UAE, ensuring quality and compliance at every step.

- End-to-End Support: Our team provides consultation, installation, training, and maintenance for your ALVO modular OR and other medical infrastructure.

Ultravision: The Leading Name in Medical Equipment and Healthcare Solutions

Your Trusted Medical Equipment Suppliers in UAE and Dubai

Ultravision is more than a supplier-we are your strategic partner for:

- Medical Equipment Supply

From surgical devices to advanced ultrasound machines, we provide the latest technology to healthcare facilities across the region.

- Medical Equipment Repair

Our certified technicians offer comprehensive medical equipment repair and preventative maintenance, ensuring peak performance and safety.

- Healthcare Solutions

Wide range of medical projects. We deliver integrated systems – from nurse call systems to pneumatic tube systems (PTS) – tailored to your facility’s needs.

- Training and Support: Ultravision offers ongoing training programs and technical support to keep your staff up to date and your equipment running smoothly.

- Local Presence: As leading medical equipment suppliers in Dubai and the wider UAE, we understand the unique demands of the region and provide fast, reliable service.

Why Healthcare Professionals Choose Ultravision

- Proven Track Record: Years of experience in delivering complex medical projects and modular OR solutions.

- Global Innovation, Local Expertise: Combining international best practices with deep knowledge of UAE healthcare regulations and standards.

- Comprehensive Service: From supply to repair, and from modular ORs to ultrasound machines, Ultravision is your one-stop partner for healthcare excellence.

Conclusion

The future of surgical care is modular, digital, and patient-centered. Healthcare professionals are looking for modular ORs that deliver rapid deployment, superior infection control, technological integration, and sustainability. Ultravision, as a leader in medical projects, healthcare solutions, and modular OR suppliers in UAE, is uniquely positioned to help your facility achieve these goals-with ALVO modular ORs and a full spectrum of medical equipment and support services.

For your next medical project or to learn more about ALVO modular OR, contact Ultravision – where innovation meets reliability in healthcare.